F&P MACHINERY PHILOSOPHY

For us F&P Machinery is not only a brand, it’s a quality mark

We are proud to affix it on our machines and see coming true our ideas, projects and the experience we have developed in so many years working on fillers and filling plant worldwide.

We like to be responsible of our product.

Our experience in this field has taught us how important it is to have; the simplicity in the use of the machine, the accuracy and consistency of manuals and documentation, and how local factors can influence the electronics and mechanics.

The attention to the needs of our customer, peculiarities of the products to be packed, packaging variety, different closure systems and the multiple combinations of these factors, including environmental aspects makes an F&P Machinery Filler “Unique”. Thoroughly taking into consideration all factors at the phase of planning ensures the quality of the finished product and the efficiency of a complete plant.

Our attitude, over the years, adapted to work with different cultures and many opportunities has influenced the way we organize ourselves, operate and realize projects.

Our experience in this field has taught us how important it is to have; the simplicity in the use of the machine, the accuracy and consistency of manuals and documentation, and how local factors can influence the electronics and mechanics.

The attention to the needs of our customer, peculiarities of the products to be packed, packaging variety, different closure systems and the multiple combinations of these factors, including environmental aspects makes an F&P Machinery Filler “Unique”. Thoroughly taking into consideration all factors at the phase of planning ensures the quality of the finished product and the efficiency of a complete plant.

Our attitude, over the years, adapted to work with different cultures and many opportunities has influenced the way we organize ourselves, operate and realize projects.

We did not research advanced technological solutions only but we imagined and implemented a new model for projecting our machines and offer tailored and affordable quality solutions.

Our filling solutions are tailored on client needs.

INNOVATIVE APPROACH TO DESIGN AND ORGANIZATION

Design

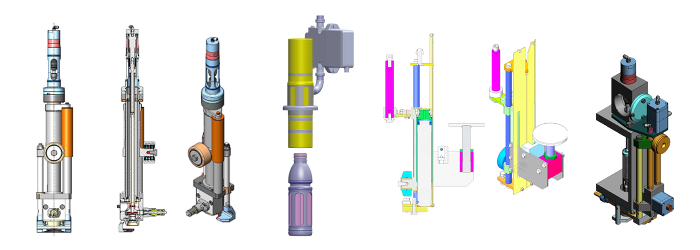

Our approach starts with the ideation of the product, for this reason we divided by modules the design of the filling machines.

Our innovative approach consists of four steps:

- The filling technologies module

- The rinsing and closure systems module

- The container transfer system module

- The structure of the filler module

- Filling Technologies: The filling technology varies depending on the type of product to be packaged, from the quality of performance to be achieved, by the number of products to be packaged and other variables and/or differences. Multiple devices can be then integrated to our filling technology to improve performance and enrich the machines capabilities.

- Rinsing and closing systems: F&P Machinery cooperates with the best producers of cappers machines and rinsers. We integrate our filling solutions with rinsing and capping solutions chosen to maximize the efficiency of the plant, treating carefully and respect the products and containers.

- Container transfer and running systems. For an effective and productive management of a bottling plant, the containers must be handled with care and respect, to avoid interference in production, product losses, breakages. Furthermore, the same filling machine may be used for containers in different sizes and materials, in this case the transport systems must provide the possibility to maneuver the containers supporting them appropriately: by the neck, the body and the bottom. A F & P Machinery can be easily projected for the filling of containers of any type of material, shape and support the containers during the critical phases of pressurization or hot filling.

- Machine Structure. Finally we define the structure of the machine, in function of the hourly productivity, by the type of rinsing and capping system to integrate, the transport systems of the container and by the optional devices chosen, to optimize space, hygiene, running costs and the degree of automation required.

Organization

Finally we define the structure of the machine, in function of the hourly productivity, by the type of rinsing and capping system to integrate, the transport systems of the container and by the optional devices chosen, to optimize space, hygiene, running costs and the degree of automation required.

With our new approach, we have improved our performance, we’ve reduced the timing from concept to delivery of the machine and developed more skills. Compared to traditional methods, namely the reengineering of existing machine projects modifying in succession individual parts.

F&P Machinery reduced machining and adjustments and can better meet customer needs.

Thanks to a matrix organization, the multiplicity of technologies and projects, a network of suppliers and partners, and above all, the long experience of our team, we can apply our method and realize your filler with full satisfaction.

Once that the project has been engineered we dedicate ourselves to the production of the parts, the assembling and wiring.

We preform accurate test and quality control in every phase of the project, to ensure with pride the F&P Machinery mark on Your Filler.

We execute accurate test and quality controls in every phase of the project to be sure to apply with pride our F&P Machinery brand on Your Filler.