HANDLING SYSTEM

All our range machines differs with only two systems of container handling.

Main features

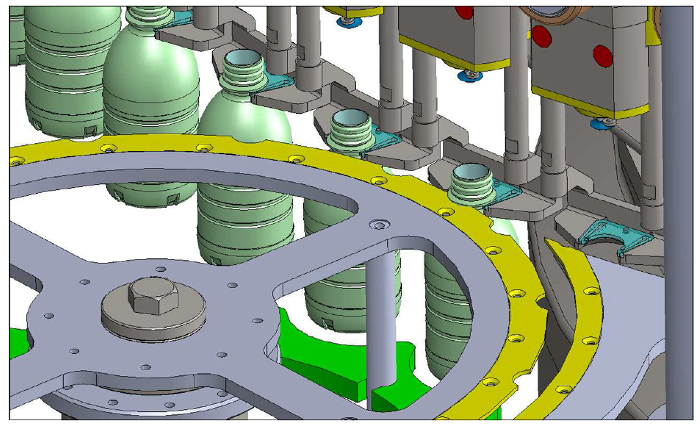

1) NECK-HANDLING system;

2) BODY-HANDLING system.

NECK-HANDLING SYSTEM advantages

- The FILLING PET and ‘designed to have no size change on the equipment.;

- If the ‘execution is with bottles of regular shape and size change is the only standard in the capper.

- Some guides of the body may be necessary for high speeds or output to the filler to avoid the “strong swing” because of the full bottle.

- In the case in which the client should perform bottles with different necks, on the NECK HANDLING we have to replace the external guides and l ‘element of the stars of neck handling.

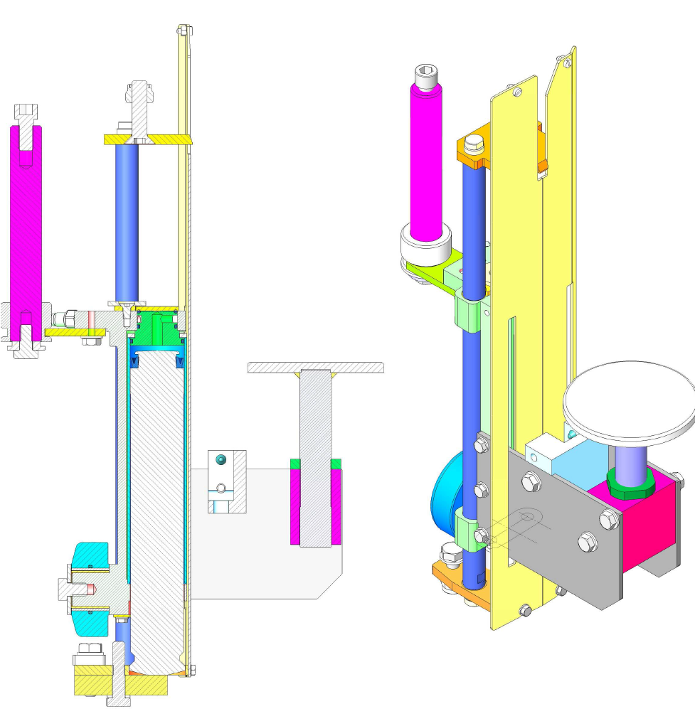

BODY-HANDLING SYSTEM advantages

- The filler GLASS is conceived with the lifting system with pneumatic jack.

- This type of pneumatic jack is also suitable for monoblocks that treat glass containers and PET

- All the stars and conveyors that guide the container during the journey are designed to obtain a change-in times moderate.

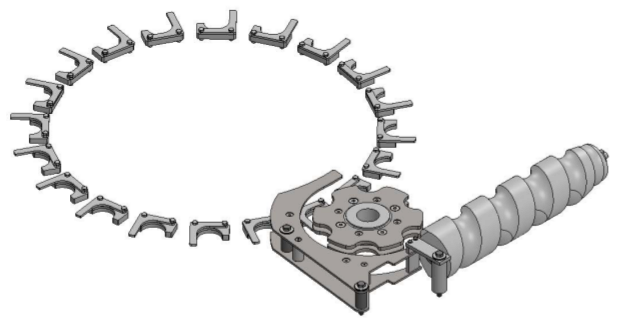

BODY-HANDLING NO LIFTER SYSTEM advantages

-

-

- System designed for monoblock cans where the lifting jack is incorporated into the filling valve.

- This system allows to have a single working plane without any change in height.

-